The Production Process of High-End Carbon Fiber Bicycle Frames

The Production Process of High-End Carbon Fiber Bicycle Frames

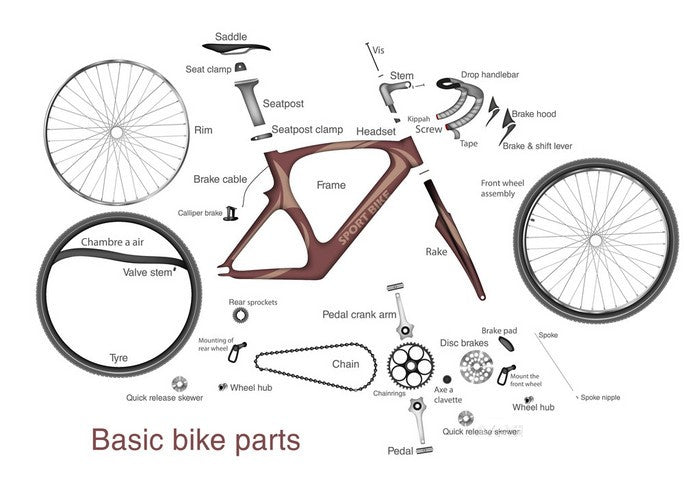

Carbon fiber is a highly sought-after material in the cycling industry due to its exceptional strength-to-weight ratio, durability, and stiffness. High-end carbon fiber bicycle frames are the pinnacle of cycling technology, providing professional riders with the ultimate in performance and efficiency.

In this blog post, we will take a look at the production process of high-end carbon fiber bicycle frames from an international perspective, covering both professional and popular terms related to bicycles.

Step 1: Design

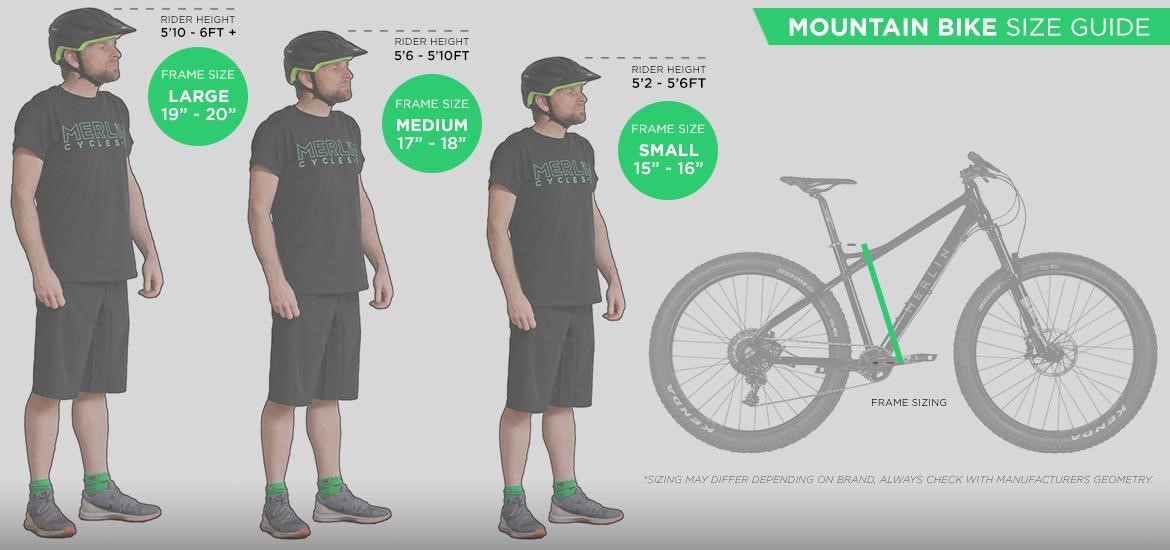

The first step in creating a high-end carbon fiber bicycle frame is the design. This process involves the use of computer-aided design (CAD) software to create a 3D model of the frame. The design must take into account factors such as the rider's height, weight, riding style, and intended use of the bike.

Step 2: Mold Making

Once the design has been finalized, the next step is mold making. A mold is created based on the design, which will be used to shape the carbon fiber into the final form of the bicycle frame. The mold must be carefully crafted to ensure that it is the correct size and shape and that it can withstand the high temperatures and pressures required for the carbon fiber molding process.

Step 3: Carbon Fiber Prepreg

The next step is the preparation of the carbon fiber prepreg. Prepreg is a carbon fiber material that has already been impregnated with a resin. It is supplied in sheets or rolls and must be handled carefully to avoid damaging the fibers. The prepreg sheets are then cut into the correct size and shape for the mold.

Step 4: Layup

Once the prepreg has been cut to the correct size and shape, the layup process begins. This involves carefully placing the prepreg sheets into the mold, ensuring that they are in the correct orientation and position. The layup process is critical as it determines the final strength and stiffness of the bicycle frame.

Step 5: Curing

Once the prepreg sheets have been placed in the mold, the curing process begins. This involves heating the mold to a high temperature and applying pressure to compress the layers of carbon fiber together. The heat and pressure cause the resin to cure, creating a strong, rigid structure. The curing process can take several hours, depending on the size and complexity of the bicycle frame.

Step 6: Finishing

The final step is finishing. This involves removing the bicycle frame from the mold and trimming any excess carbon fiber. The frame is then sanded and polished to create a smooth, glossy surface. The finishing process can also include the application of decals, paint, or other customization options.

Conclusion

The production process of high-end carbon fiber bicycle frames is a complex and multi-step process that requires a high degree of precision and expertise. From the design and mold making to the layup and curing process, each step is critical in creating a high-quality carbon fiber bicycle frame that is strong, lightweight, and durable. With its superior strength-to-weight ratio and versatility, it's no wonder that carbon fiber has become such a sought-after material in the cycling industry. For professional riders, a high-end carbon fiber bicycle frame is the ultimate expression of performance and technology.

0 Comments